Our History

Since 1945, our unwavering commitment to innovation, growth and quality has been the driving force behind our transformation into one of the largest manufacturers of high performance composites in the world.

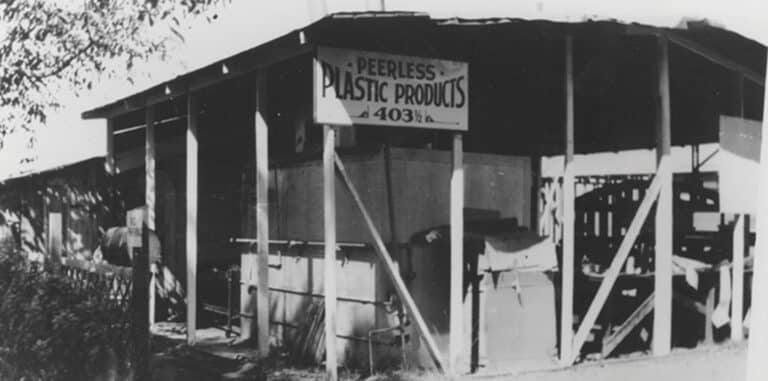

The Gill Corporation began in a rented garage in Montebello, California and currently resides in an eight building complex on Easy Street in El Monte, California, with subsidiaries in Maryland, France and Northern Ireland.

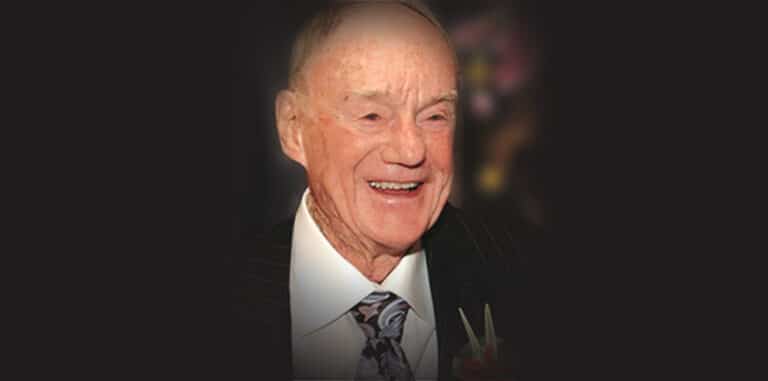

The Gill Corporation was founded on September 11, 1945 by a man who believed that “plastics” was the future – Merwyn “M.C.” Gill. He started the company in a garage in Montebello and, today, it is the oldest, continuously operating manufacturer of advanced composites for the aviation industry in the world.

The company originally produced products for the consumer market. Some were unique, like a plastic wall covering that was before its time and balsa bat and cork ball baseball game set. But, after seven years of struggling, an opportunity emerged to manufacture belly baggage compartment wall linings for Douglas Aircraft’s DC-6.

The company grasped the opportunity and we’ve been in commercial aviation since that time. The company still makes “cargo liner” today, but it’s a different product than it was then.

The Gill Corporation began as Peerless Plastic Products, Inc.

Bob Usher, center fielder Los Angeles Angels, endorsed Bat N Ball.

The Corporation received first cargo liner order from Douglas Aircraft.

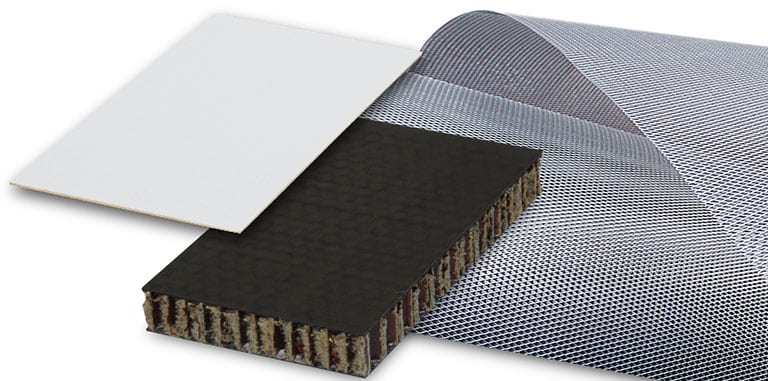

Discovered secret formulation to make Gilliner® 1066 the most popular airplane cargo liner in the world.

M.C. Gill moved the business to El Monte and into Building #1.

Manufactured bulletproof flooring for helicopters used in the Vietnam War.

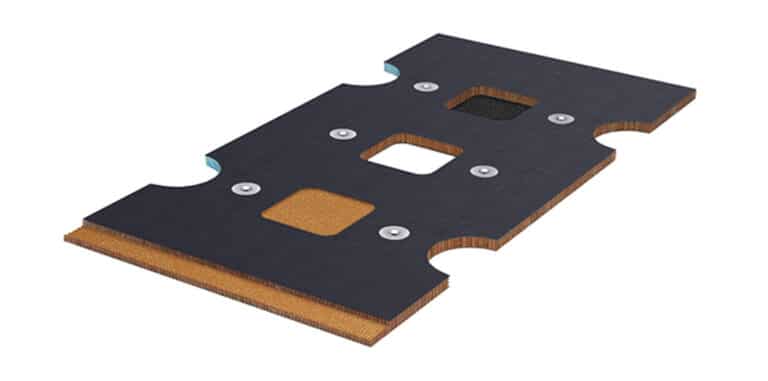

Gillfloor® 5007C was invented and sold to airlines as replacement floor panel.

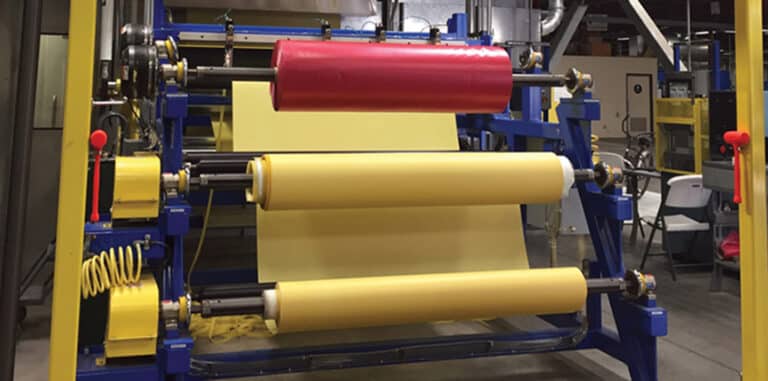

Designed and built our first woven prepreger.

Began developing and manufacturing our own adhesives.

Developed meta-aramid honeycomb product.

Received first meta-aramid honeycomb award from an OEM.

Awarded first contract for detailed floor panels for MD80s and MD90s

Achieved an OEM qualification for aftermarket panels.

OEM floor panel qualification completed.

Won the largest OEM core contract in company history.

Acquired Insoleq (TGC-Europe.)

Acquired Castle (now part of TGC in El Monte.)

Acquired Alcore and Alcore Brigantine (TGC-Maryland and TGC-France)

Awarded the majority of OEM raw stock floor panel business.

Sponsored the creation of the Composites Merit Badge for the Boy Scouts.

Developed and qualified para-aramid honeycomb product.

Completed development of portfolio of ultra lightweight honeycombs, floor panels, interior panels, cargo compartment liners and lightning strike protection using new materials and processes.

Company founder, M. C. Gill, passed away

Awarded largest floor panel fabrication contract from an OEM in company history.

Awarded another OEM floor panel fabrication contract

Stephen Gill won The Gilbert W. Speed Award Honoring Outstanding Leadership and Collaboration.

Qualified our second woven prepreger

Stephen Gill was entered into The Western Plastics Pioneers Hall of Fame

Qualified GillVANA®, new sound dampening floor panel.

The Gill Corporation celebrates 75 years of success.