波音 787 夢想飛機就是這樣一種飛機,其設計重點是提高效率、降低運營成本和減少環境影響。 B787 採用 50% 複合材料的輕型結構,可將燃油消耗和二氧化碳排放量減少 20-30%,是第一款在機身和機翼中使用碳纖維複合材料的大型商用飛機。

This aircraft has enabled airline operators to optimize fleet and network performance and offers increased “point-to-point” service, as it has exceptional efficiency, capacity, and range. As of December 2022, total orders for B787 reached 1,608, with 1,039 aircraft delivered.

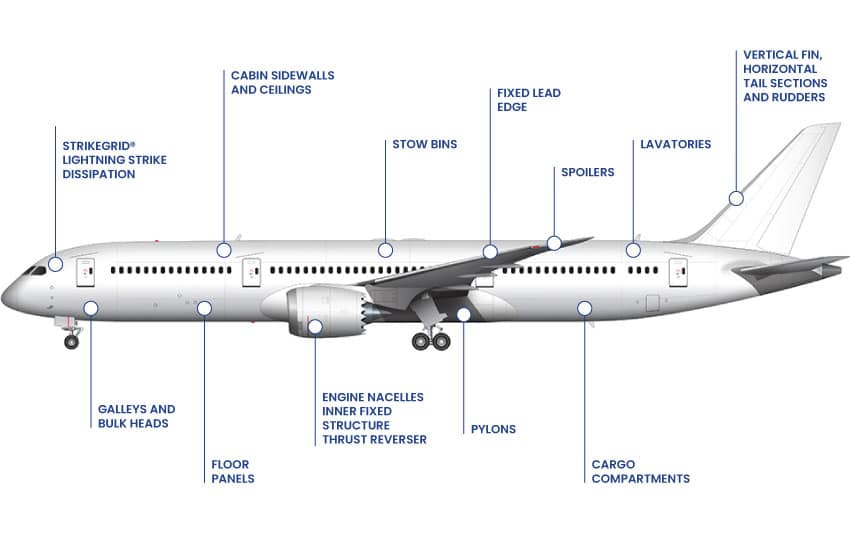

TGC’s product development program was launched in 2000, and it led to the development and characterization of ultralightweight honeycombs, floor panels, interior panels, cargo compartment liners, and lightning strike protection, using a combination of new materials and processes. The scope of this program included the development of a new para-aramid honeycomb, formulation of new resin matrices, development of a lighter weight film adhesive, and tailoring of the reinforcements, aerial fiber weight, and resin content of prepregs. Today, TGC supports the B787 program with a portfolio of ultra-lightweight honeycomb, machined honeycomb details, floor panels, interior panels, cargo compartment liners, lightning strike protection, and fabricated floor panel kits.

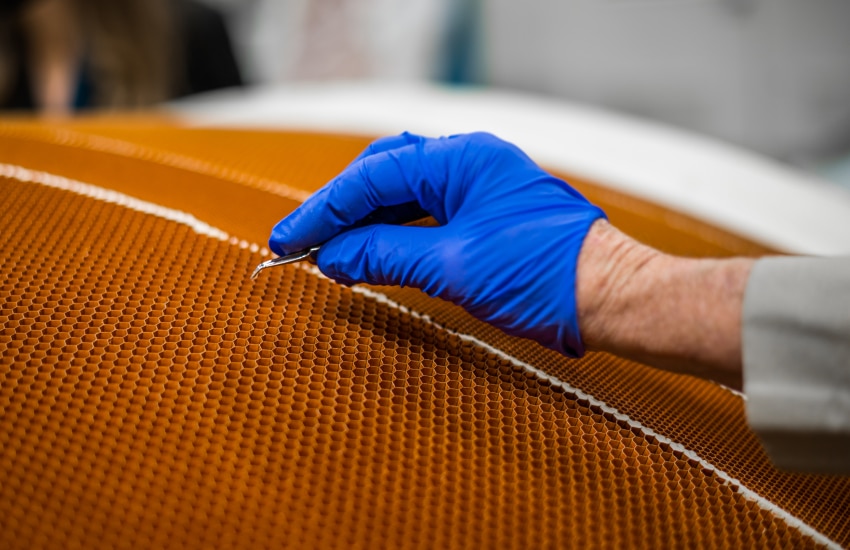

As a saturable substrate, para-aramid becomes a true composite cell wall when converted to honeycomb, yielding exceptional shear strength and modulus, stiffness, durability, fatigue, and hot/wet properties. These superior characteristics make it possible to achieve values that are equal to or higher than meta-aramid at a significant weight reduction of core density. Most configurations of Gillcore® HK can be manufactured using different thicknesses of para-aramid paper, allowing for optimization of key properties geared to specific applications.

For the B787 program, TGC developed a range of floor panels that would meet or exceed the mechanical properties of the applicable Types of BMS 4-17 and BMS 4-20 at a significantly reduced weight. The weight savings, achieved in part by replacing the meta-aramid honeycomb with para-aramid honeycomb, are highlighted by type. Gillfab® 4809, qualified to BMS 4-20, is an ultra-lightweight, high-strength floor panel made from unidirectional carbon fiber-reinforced epoxy facings bonded to Gillcore® HK para-aramid honeycomb core. The outer facing surfaces feature a thin glass isolation barrier to prevent galvanic corrosion.