Depuis l'avènement des moteurs à réaction il y a plus de 65 ans, l'aviation commerciale a été révolutionnée et la demande pour des conceptions d'avions plus avancées a augmenté.

Les avancées récentes incluent des moteurs plus efficaces, des changements de conception aérodynamique et des ailes et l'utilisation croissante de matériaux composites dans la construction aéronautique.

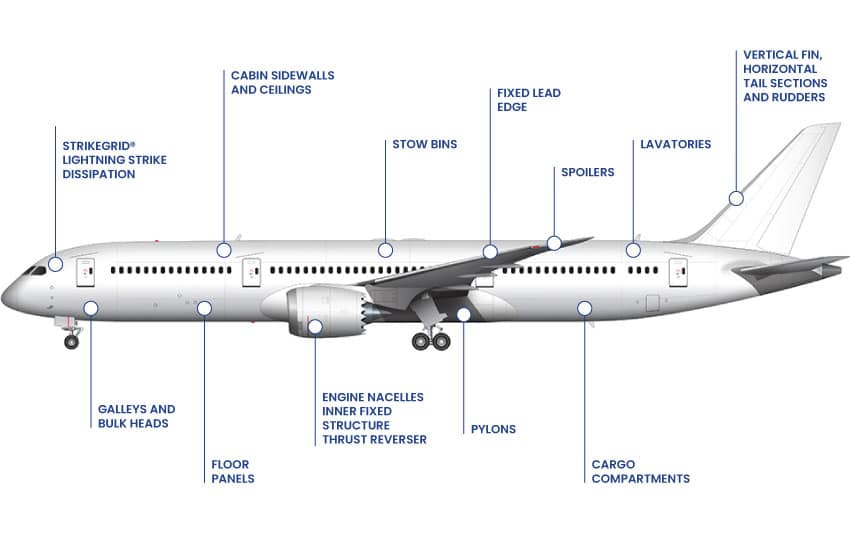

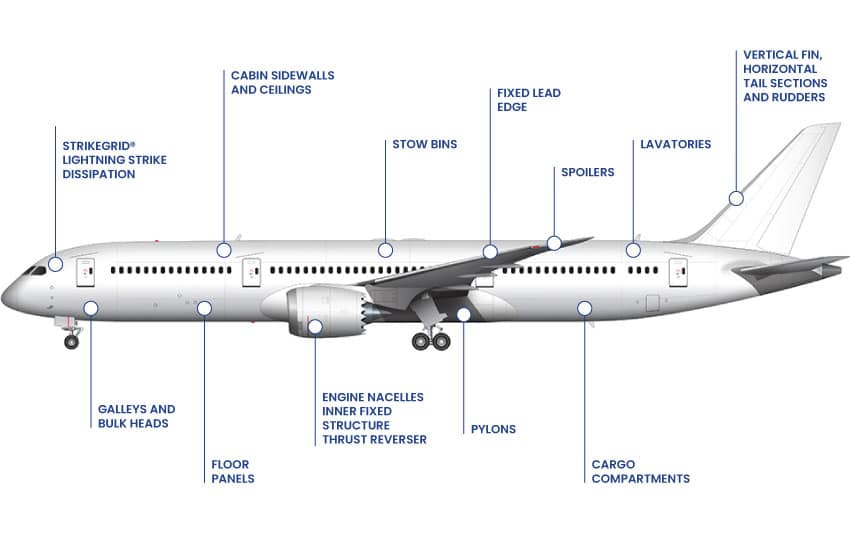

Le Boeing 787 Dreamliner est l'un de ces avions qui a été conçu pour se concentrer sur l'efficacité, la réduction des coûts d'exploitation et l'impact environnemental. Avec des structures légères en composite 50%, le B787 réduit la consommation de carburant et les émissions de CO2 de 20-30% et est le premier avion commercial majeur à utiliser un composite en fibre de carbone dans le fuselage et les ailes.

This aircraft has enabled airline operators to optimize fleet and network performance and offers increased “point-to-point” service, as it has exceptional efficiency, capacity, and range. As of December 2022, total orders for B787 reached 1,608, with 1,039 aircraft delivered.

L'un des principaux contributeurs au succès du Boeing 787 Dreamliner est The Gill Corporation (TGC).

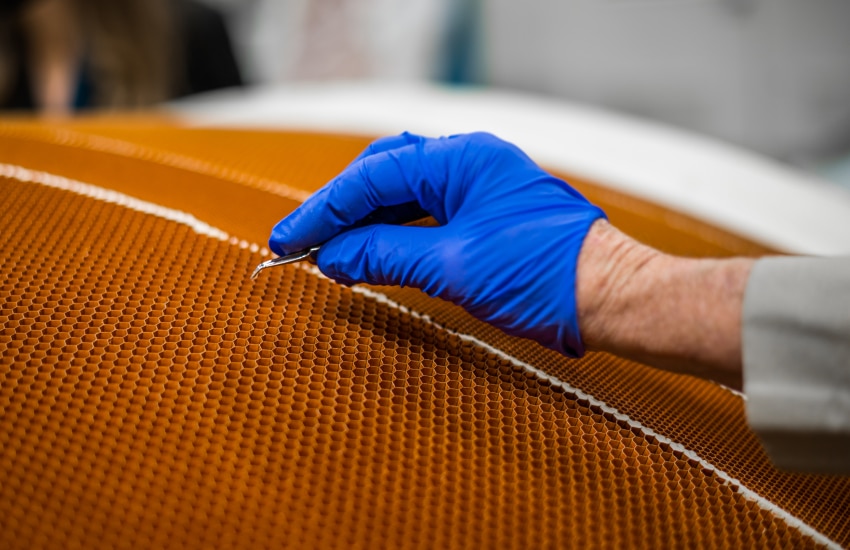

TGC’s product development program was launched in 2000, and it led to the development and characterization of ultralightweight honeycombs, floor panels, interior panels, cargo compartment liners, and lightning strike protection, using a combination of new materials and processes. The scope of this program included the development of a new para-aramid honeycomb, formulation of new resin matrices, development of a lighter weight film adhesive, and tailoring of the reinforcements, aerial fiber weight, and resin content of prepregs. Today, TGC supports the B787 program with a portfolio of ultra-lightweight honeycomb, machined honeycomb details, floor panels, interior panels, cargo compartment liners, lightning strike protection, and fabricated floor panel kits.

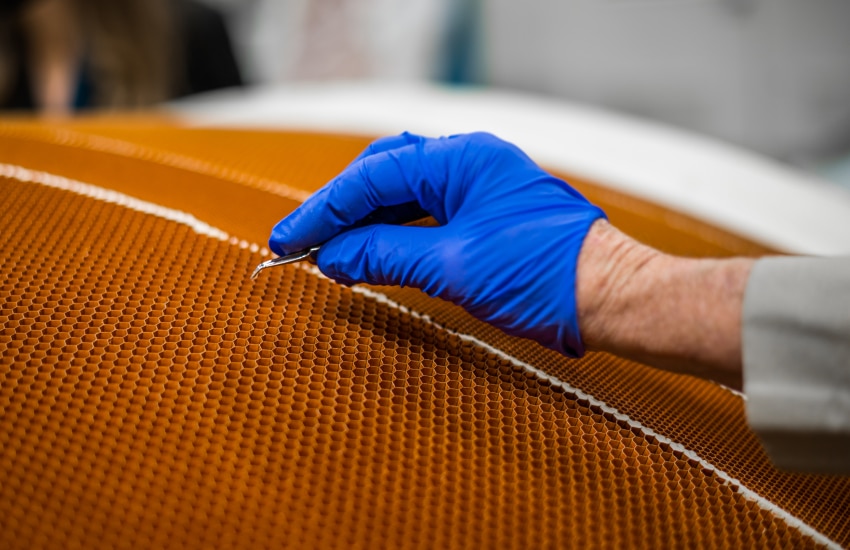

Gillcore® HK is a high-performance honeycomb manufactured using para-aramid paper that is coated with phenolic resin.

As a saturable substrate, para-aramid becomes a true composite cell wall when converted to honeycomb, yielding exceptional shear strength and modulus, stiffness, durability, fatigue, and hot/wet properties. These superior characteristics make it possible to achieve values that are equal to or higher than meta-aramid at a significant weight reduction of core density. Most configurations of Gillcore® HK can be manufactured using different thicknesses of para-aramid paper, allowing for optimization of key properties geared to specific applications.

For the B787 program, TGC developed a range of floor panels that would meet or exceed the mechanical properties of the applicable Types of BMS 4-17 and BMS 4-20 at a significantly reduced weight. The weight savings, achieved in part by replacing the meta-aramid honeycomb with para-aramid honeycomb, are highlighted by type. Gillfab® 4809, qualified to BMS 4-20, is an ultra-lightweight, high-strength floor panel made from unidirectional carbon fiber-reinforced epoxy facings bonded to Gillcore® HK para-aramid honeycomb core. The outer facing surfaces feature a thin glass isolation barrier to prevent galvanic corrosion.

The Boeing 787 Dreamliner has changed the way people travel, and it is a symbol of technological advancement in the aviation industry. TGC’s contribution to the program has helped to make the aircraft lighter, more efficient, and environmentally friendly. This shows that innovation is the key to progress and growth, and with the right approach, we can continue to make great strides in commercial aviation.