Honeycomb core has provided the highest strength-to-weight ratio of any structural material for decades.

The Gill Corporation pioneered the use of balsa wood as a natural, lightweight, high-strength core in the 1950s. We introduced metallic honeycomb cores using very high-strength, lightweight aluminum foil in the mid 1950s.

With over 50 years’ structural core experience, The Gill Corporation is a leading manufacturer offering a diverse product portfolio with expansive value-add capabilities. Our meta-aramid honeycomb cores were introduced in the 1980s, followed by para-aramid honeycomb cores in the 2000s and Fiberglass honeycomb cores in the 2010s.

Today, our honeycomb cores have been qualified by virtually every manufacturer of aircraft and aerospace vehicles, and are designed into numerous ground, rail, marine and specialty industrial applications. We offer standardized core materials and highly customized core products based upon our proprietary resin formulations, node bond adhesives and advanced production processes.

Metallic Honeycomb

Metallic honeycomb provides lightweight, high-strength solutions with corrosion resistance for exterior aircraft applications such slats, spoilers, flaps, engine nacelle and thrust reverser structures, interior structures and monuments, floor panels, and non-aerospace applications including collision and energy absorption, flooring and interiors of train and subway cars, specialty transportation casks and building materials, as well as high-performance racing yachts.

Metallic honeycomb is prominently used in space applications for rocket boosters, nose cones and heat shields, as well as solar and satellite structures.

Honeycomb Materials are Available In Many Forms:

- Block

- Sliced

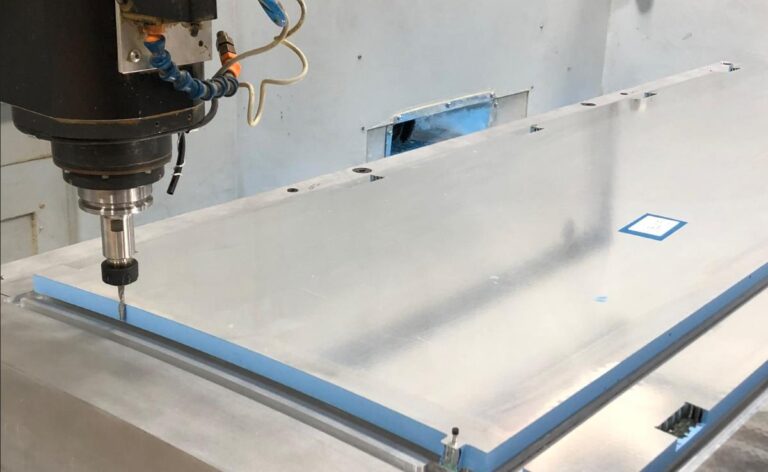

- Machined

- Bonded structures

- Composite core sandwich panels

- Unexpanded

Non-Metallic Honeycomb

Non-metallic honeycomb provides lightweight, high-strength performance for exterior and interior aircraft applications.

A passenger in an airliner is essentially encapsulated by parts made from non-metallic honeycomb, including engine nacelle components, spoilers, flap track fairings, wing to body fairings, floors, sidewalls, overhead bins, lavatories, galleys, doors and more.

Non-metallic honeycomb has become a key performance enabler of advanced lightweight manned and unmanned aircraft and vehicles.

Value Added Honeycomb Services Include:

- Trimming

- Chamfering

- Potting

- Details, bonded

- Assemblies and core kits

- Thermal forming to contour

- Septum and splice bonding

- Film adhesive stabilization

- 3, 5 and 6-axis CNC machining capabilities