The Gill Corporation is a pioneer in the field of innovative, lightweight advanced composite solutions.

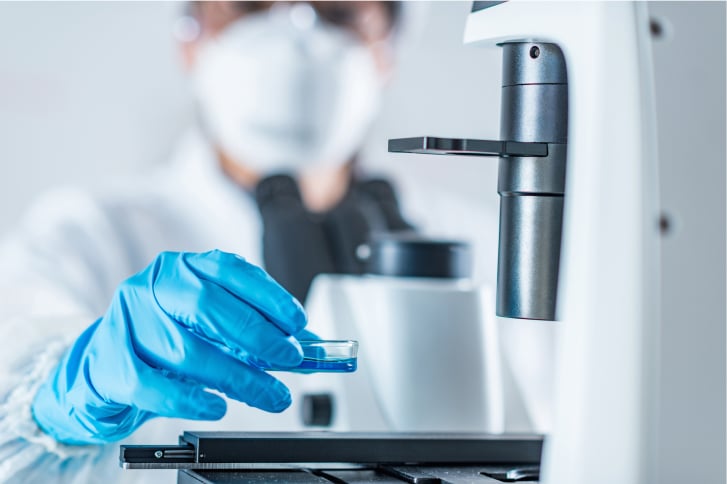

Our scientists are committed to addressing customer requirements while offering excellence in product performance. This begins with the base formulations of our resin systems.

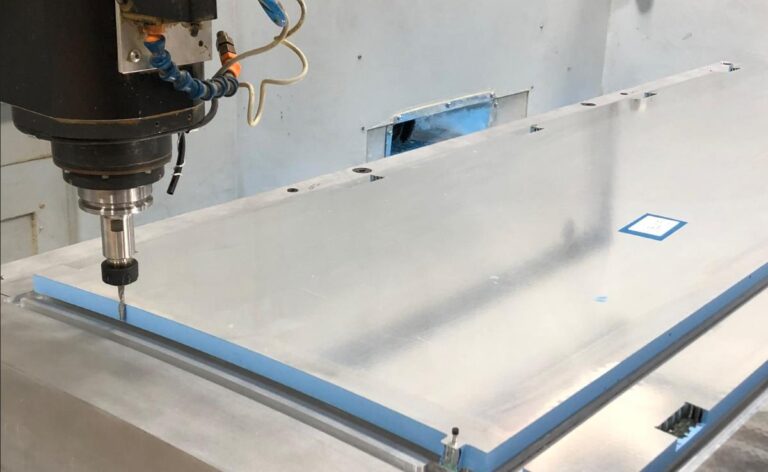

Vertical integration of resin mixing, prepreg, adhesive and core manufacturing has been key to our ability to tailor the best solutions to the challenges our customers encounter.

The Gill Corporation’s research and development (R&D) team continues the long tradition of innovation in the development of forward-thinking product development while maintaining strong technical support of existing products.

We believe that a winning product begins with understanding and identifying unmet customer needs and partnering with our industry counterparts to develop value-added products that improve performance while reducing operating costs.

Latest Innovations

Our team of scientists is dedicated to ensuring that our products comply with stringent flammability regulations, while minimizing the use of hazardous chemicals, and we are actively exploring the use of alternate resins and flame retardants to develop products that challenge the norm.

To achieve lightweight solutions that meet critical flammability and mechanical requirements, our R&D team is also incorporating new features, such as acoustic dampening and thermal insulation, into our GillVANA® and GillFISTS® product lines.

GillVANA® and GillFISTS® products are manufactured using environmentally friendly processes, and our R&D team is committed to developing “green” future product line chemistries.

Our Advanced R&D Tools Include:

- Seven UTMs (Universal Test Machines) of various load capability

- DSC (Differential Scanning Calorimetry), two DSCs with different capabilities

- TMA (Thermo-mechanical analyzer)

- TGA (Thermo-gravimetric analyzer)

- FTIR (Fourier Transform Infrared)

- RAMAN (spectroscopy for vibrational, rotational, and low-frequency modes in a system)

- NIR (Near-Infrared)

- Rheometry, one capillary and two rotational

- Advanced microscopy, three microscopes with differing capabilities

- Acoustic long beam testing

- Multiple ovens with differing temperature capability

- 5-gallon reactor for formulation development