We manufacture extreme precision parts, on time, with the highest degree of customer service.

Our newest business unit, Precision Machining, is focused on the machining and forming of metallics and assembly of metallic structures.

This manufacturing capability provides The Gill Corporation with a unique opportunity to support composite programs with metallic content in addition to providing stand-alone machined parts and assemblies.

Precision Machining maintains DPD/MBD approvals from airframe OEM as well as having Nadcap approval for liquid penetrant inspection. Our extensive range of state-of-the-art equipment allows us to offer our customers extreme precision, fast turn-around and competitive pricing

We have a range of advanced inspection equipment to ensure the highest level of quality for our products.

With our advanced inspection equipment and expertise in non-destructive testing, we are committed to delivering products of the highest quality to our customers.

Manufacturing Expertise

- 3 Axis machining of hard alloys with an

emphasis on Ti 6AL-4V

Plate | Extrusions | Sheet - Fabrication of complex assemblies

- Forming of aluminum and titanium sheet

- Surface treatments; primer and top coat applications

- Non-destructive testing; Nadcap certified liquid penetrant inspection

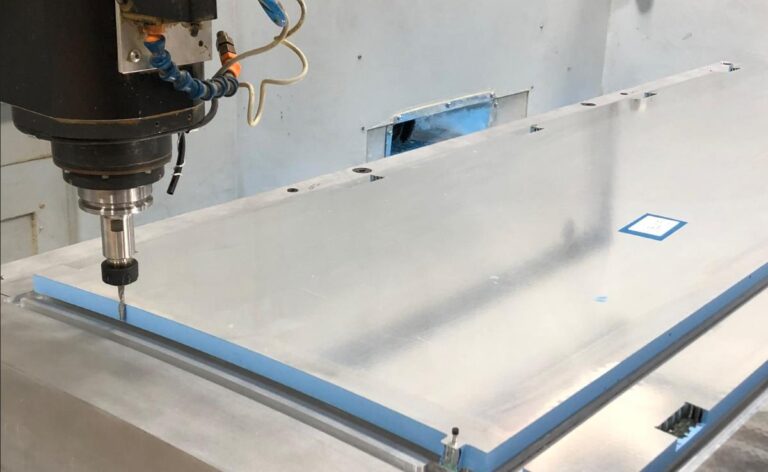

Our Machining Centers

- All of our machining centers have robust frames for stable and rigid machining platforms

- High-torque-value machines ideal for hard-alloy work

- Thru-spindle and 1000psi coolant pumps for max chip removal

- 50 taper tool holders

- Equipped with Renishaw touch probe technology for in-cycle measurement

- Utilize the latest high-performance cutting tools for maximum material removal and optimal part quality

Inspection Equipment

ROMER INSPECTION ARM

Function: Manual Dimensional Inspection

Size: 8.2 ft. Measuring Range/ 7 Axis

Comments: Volumetric Accuracy: +/- 0008; Single Point Accuracy: +/- 0.0011; Polyworks Software

FARO INSPECTION ARM

Function: Manual Dimensional Inspection

Size: 8 ft. Measuring Range/ 7 Axis

Comments: Volumetric Accuracy: +/- 0016; Single Point Accuracy: +/- 0.0011; Polyworks Software

HEXAGON METROLOGY 7.10.7SF

Function: Brown & Sharpe DCC Programmable Measuring Machine

Size: 28″ x -39.8″Y -26.8″ Z Measuring Capacity

Comments: Single Point Accuracy: +/- .000013; PC DMIS Software

FABRIVISION

Function: Flat Pattern Scanner

Size: 48″ Wide x 72″ Long Measuring Capacity

Comments: Optical Scanner for Measuring/Inspection of Flat Patterns

NON-DESTRUCTIVE TESTING

Function: Liquid Penetrant Inspection

Size: 48″ x 48″ x 30″ Tanks

Comments: Special Process Inspection; ASTM-1417, BAC5423, and BSS7039