The Gill Corporation provides customers around the world with value added products by optimizing vertically integrated production processes.

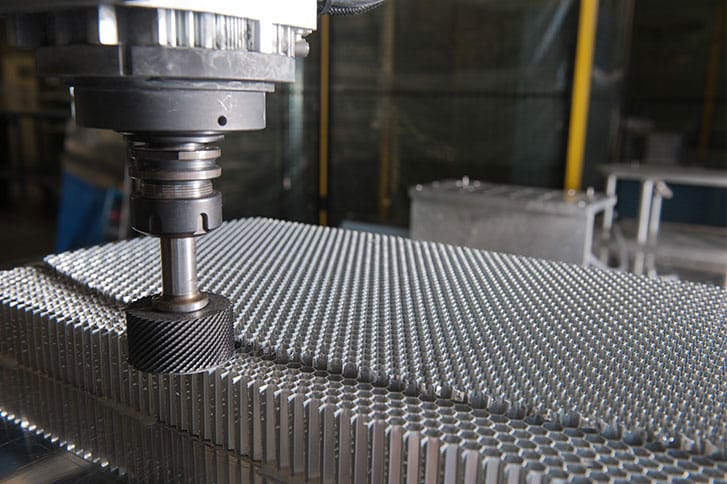

Honeycomb special processing begins with production of a wide variety of metallic and non-metallic honeycomb cores that can be sized to maximize yields of core details, assemblies and parts.

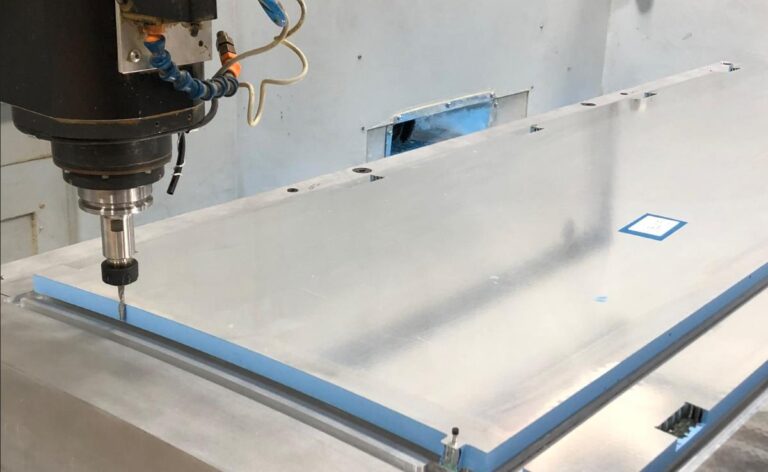

Utilizing our 3-, 5- and 6-axis CNC machines, our experienced engineering and CNC programming teams combine their process knowledge, which results in close tolerance machined honeycomb details and large complex core assemblies.

Our vast portfolio of value added, special processing capabilities transforms slices of metallic and non-metallic honeycomb into contoured bonded assemblies, delivered to customers spanning aerospace, space, defense, military, marine, rail and other industries.

Value added services are tailored to meet or exceed customer expectations while eliminating waste, time and costs. These services include custom packaging, kitting and just in time delivery.

Specialty and Value Added Honeycomb Solutions

We specialize in developing innovative solutions for various industries. We offer impact limiters with unique crush characteristics that are ideal for containing hazardous materials, including spent nuclear fuel rods. In addition, we provide kinetic energy absorption products that cater to the needs of high-speed transportation applications such as trains, cars, highways, and aviation.

Process Specifications

The Gill Corporation maintains ISO 9001:2015, AS 9100 Rev. D and Nadcap quality approvals.

We have multiple qualified specifications for numerous customers such as:

- Airbus

- AVIC

- Avcorp

- Boeing

- Boeing Commercial

- Boeing Defense

- Collins

- Dassault

- Ducommun

- Evergreen

- FACC

- Fokker

- GE Aviation

- GKN

- Gulfstream

- Honeywell

- IAI

- KAI

- KAL

- Kongsberg

- Leonardo

- Lockheed Aeronautics

- MHI

- MRAS

- Northrop Grumman

- Raytheon

- RUAG

- SACC

- Safran

- SAMC

- Sikorsky

- Sofitec

- Sonaca

- SpaceX

- Spirit

- Strata

- Triumph

- XIAN Aircraft

Special Processing Capabilities Include:

- 3-, 5-, and 6-Axis CNC Machining

- CNC Programming

- Planform Trimming

- Horizontal Sawing

- Chamfering

- Cuette Milling and Expansion of Shapes

- Routing of Doublers or Rebates

- Core Slotting

- Roll Forming

- Arc Expansion

- General Handwork

- Potting

- Heat Forming

- Custom Contouring (SHAPEGRID®)

- Splice and Septum Bonding

- Core Stabilization

Our Special Processing Aerospace Applications Include:

- Vertical Fin and Horizontal Tail Sections

- Rudders

- Vertical Torque Box

- Elevators

- Winglets

- Flaps

- Spoilers

- Ailerons

- Slats

- Pylon Fairings

- Thrust Reversers

- Engine Nacelles

- Wing to Body Fairings

- Landing Gear Doors

- Radomes

- STRIKEGRID® Lightning Strike Dissipation