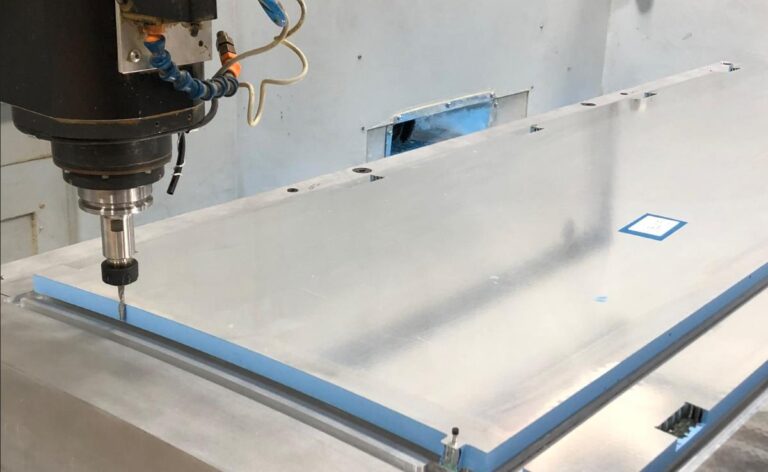

Laminate manufacturing produces strong and lightweight composite materials for demanding applications.

Fiber reinforced composites are produced with processes established specifically for the resin matrix chemistry and product construction.

All The Gill Corporation designs feature thermosetting polymer resins that are cured using precise heat and pressure combinations. TGC engineering established critical production processes to blend resin with reinforcement to ensure uniform fiber coating before the matrix is thermoset.

This is accomplished by using either wet lay-up or pre-impregnating the reinforcement with resin in a partially polymerized state known as B-stage prior to lay-up. Polyester and vinyl ester laminates are produced in sheet or roll form. The roll form involves a rotary cure press where dry reinforcement is submerged in the resin to saturate the fibers.

This ‘wet’ reinforcement transfers onto the heated pressing belt to cure the laminate. For phenolic laminates produced on the rotary press, pre-impregnated reinforcement is used instead of wet lay-up materials.

Fiber Reinforced Plastic (FRP)

Fiber reinforced plastics combine a polymer resin matrix with a fiber reinforcement to yield a high strength, lightweight composite material that is suitable for structural, and abrasion resistant fire barrier applications. The reinforcement allows for a variety of mechanical and physical properties to be designed into the laminate while the resin matrix surrounds and supports the reinforcement for optimum translation of the fiber properties. The resin mix can be modified with additives to improve characteristics such as flammability, impact and edge bearing strength.

Fiber Reinforced Plastic

Fiber reinforced plastics are the foundation of TGC’s cargo liner and sandwich panel designs and can be tailored to meet a specific set of requirements by modifying:

- Resin matrix

- Type of reinforcement

- Amount of reinforcement

- Orientation of the fiber

- Surface veil

- Fabrication process

Specialty Laminate Applications

- Edge-attachments for aircraft windshields and transparencies

- Fuel cell lining

- Backing for non-textile flooring (NTF)

- Overhead stowage bin repair

- High-performance laminates

- Abrasion barriers, impact barriers and fire barriers

- Fiberglass — epoxy, phenolic and polyester resins