We revolutionized aerospace fabrication, assembly and kitting in the early 1990s, and we're on its forefront today.

Starting in the early 1990s, we began offering value-added services like fabrication and assembly to our raw form sandwich panels. This allowed us to deliver floor panels that were “drop-in ready” for installation on MD-80 aircraft at the McDonnell Douglas assembly facility.

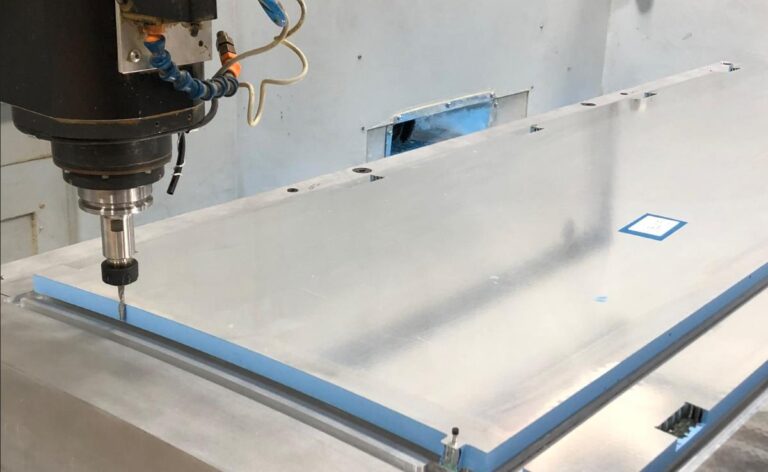

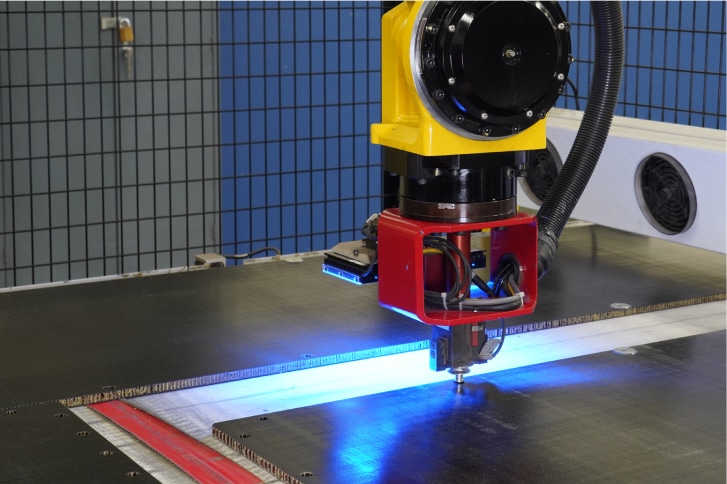

With skilled personnel and modern equipment, we can precisely machine parts, install components, inspect and ship parts to meet customer requirements.

From BAE 146 to MD-11 programs, we have supplied fabricated products for a variety of airplane programs. Our expertise in fabricating parts for sandwich panels, laminates, and assemblies — including composite and metallic materials, dog houses, and interior monuments, has made us a go-to partner in the industry.

MAKE-VS-BUY

TGC conducts make-vs-buy decisions on high-value components that can be made internally to reduce costs and lead times and improve the quality of the final product. To support industry cost challenges, TGC invested in equipment, process development and expertise with advanced 5-axis CNC machines to make Titanium and Aluminum components.

FABRICATION SOLUTIONS ARE AVAILABLE IN MULTIPLE FORM FACTORS

- Flat, curved, formed, or contoured

- Composite and metallic raw materials

- Simple machined details, bonded parts, complex assemblies or complete shipset kits

MACHINED AND DETAILED LAMINATES AND PANELS

The 3-axis machines in our Fabrication COEs are capable of cutting a variety of materials.

- Panels

- Laminates

- Protective layers

FABRICATED ASSEMBLIES

Based on customer designs, TGC expertly installs and attaches both purchased and vertically integrated components.

- Edge fill and edge seal

- Inserts, insulation blankets, vibration damping and sound damping

- Anti skid tapes, part markings and labels

- Fittings, intercostals, splice plates

FABRICATION FOR OEMS

- Airbus A380 cockpit and E/E bay panel fabrication

- Boeing 777, 777X, 787 main deck and cargo floor panel fabrication

- Irkut MC 21 shipset floor panel fabrication

- Airbus A350 oxygen storage racks

- IAI G280 cabin, cargo bay floor and sidewalls

- Gulfstream G550, G600, G700 interior structural walls

- Boeing / USAF Air Force One

- Boeing 737BCF

- Various other programs

FABRICATION FOR AFTERMARKET

- OEM qualified materials

- Proprietary designs offering improved durability over OEM and competitors products

- Parts Manufacturer Approval (PMA) solutions

- Flight crew seat repair

- Sewing (seat upholstery, seat cushions, etc.)

- Passenger to Freighter conversions:

– ATR42/72

– Airbus A320/A321/A330

– Boeing 737/747/757/767/777

– Saab 340 & 2000

Our Fabrication, Assembly & Kitting Applications Include:

- Passenger and Cargo compartments

- Floors

- Side Walls

- Ceilings

- Stowage bins

- Lavatories

- Galleys

- Cockpits

- E/E bays

- Maintenance areas

- Bulkheads

- Dividers

- Dog houses