We are one of the world's largest manufacturers of honeycomb panels.

Providing innovative solutions for the world’s most crucial industries.

Capabilities

An extensive collection of documents, here at your fingertips.

Resources

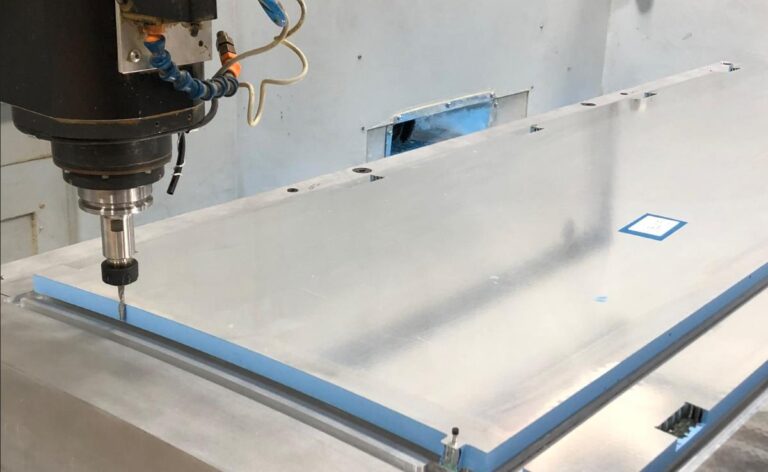

Collaborating across continents to provide innovative composite solutions.

El Monte, California – 1 October 2002 – A Dielectric Press has been added to M.C. Gill Corporation’s arsenal of equipment used to make the best honeycomb in the world. To create GillcoreT honeycomb, precision lines of adhesive are printed onto the appropriate Nomex® or Kevlar® paper. The paper is then sheeted and stacked, so that once the adhesive is cured, they can be expanded to create the uniform cells that make up the honeycomb. A critical step in the fabrication process involves heating the block under pressure so that the adhesive cures properly. In conventional systems the block is cured using oil or steam heat. Using this traditional system, the heat must slowly migrate from the outside of the block into its interior until it fully penetrates the entire block for a prescribed length of time. Heating and curing a block by this method can take upwards of 30 hours. In contrast, the new Dielectric Press used by M.C. Gill Corporation can cure that same block in less than one hour. This is possible because heat is generated evenly throughout the entire block using radio frequency energy. Dielectric heating works when certain materials are positioned in an alternating electric field, their molecules rotate and move laterally. This movement occurs millions of times per second as the molecules attempt to align with the changing field. This generates heat very quickly and evenly throughout the block, much like your microwave oven at home works. The honeycomb block to be cured is placed in the Dielectric Press between two conducting plates. These plates are part of an electrical circuit and act as electrodes. The paper block becomes the “dielectric” of a capacitor. The process is simple and precise, providing our customers the benefits of faster turnaround times, excellent uniformity and improved quality. The monitoring of the process includes: temperature, time and pressure. M.C. Gill product quality improves because the material is subject to less heat history and is cured move evenly.

El Monte, California – 1 October 2002 – A Dielectric Press has been added to M.C. Gill Corporation’s arsenal of equipment used to make the best honeycomb in the world. To create GillcoreT honeycomb, precision lines of adhesive are printed onto the appropriate Nomex® or Kevlar® paper. The paper is then sheeted and stacked, so that once the adhesive is cured, they can be expanded to create the uniform cells that make up the honeycomb. A critical step in the fabrication process involves heating the block under pressure so that the adhesive cures properly. In conventional systems the block is cured using oil or steam heat. Using this traditional system, the heat must slowly migrate from the outside of the block into its interior until it fully penetrates the entire block for a prescribed length of time. Heating and curing a block by this method can take upwards of 30 hours. In contrast, the new Dielectric Press used by M.C. Gill Corporation can cure that same block in less than one hour. This is possible because heat is generated evenly throughout the entire block using radio frequency energy. Dielectric heating works when certain materials are positioned in an alternating electric field, their molecules rotate and move laterally. This movement occurs millions of times per second as the molecules attempt to align with the changing field. This generates heat very quickly and evenly throughout the block, much like your microwave oven at home works. The honeycomb block to be cured is placed in the Dielectric Press between two conducting plates. These plates are part of an electrical circuit and act as electrodes. The paper block becomes the “dielectric” of a capacitor. The process is simple and precise, providing our customers the benefits of faster turnaround times, excellent uniformity and improved quality. The monitoring of the process includes: temperature, time and pressure. M.C. Gill product quality improves because the material is subject to less heat history and is cured move evenly.