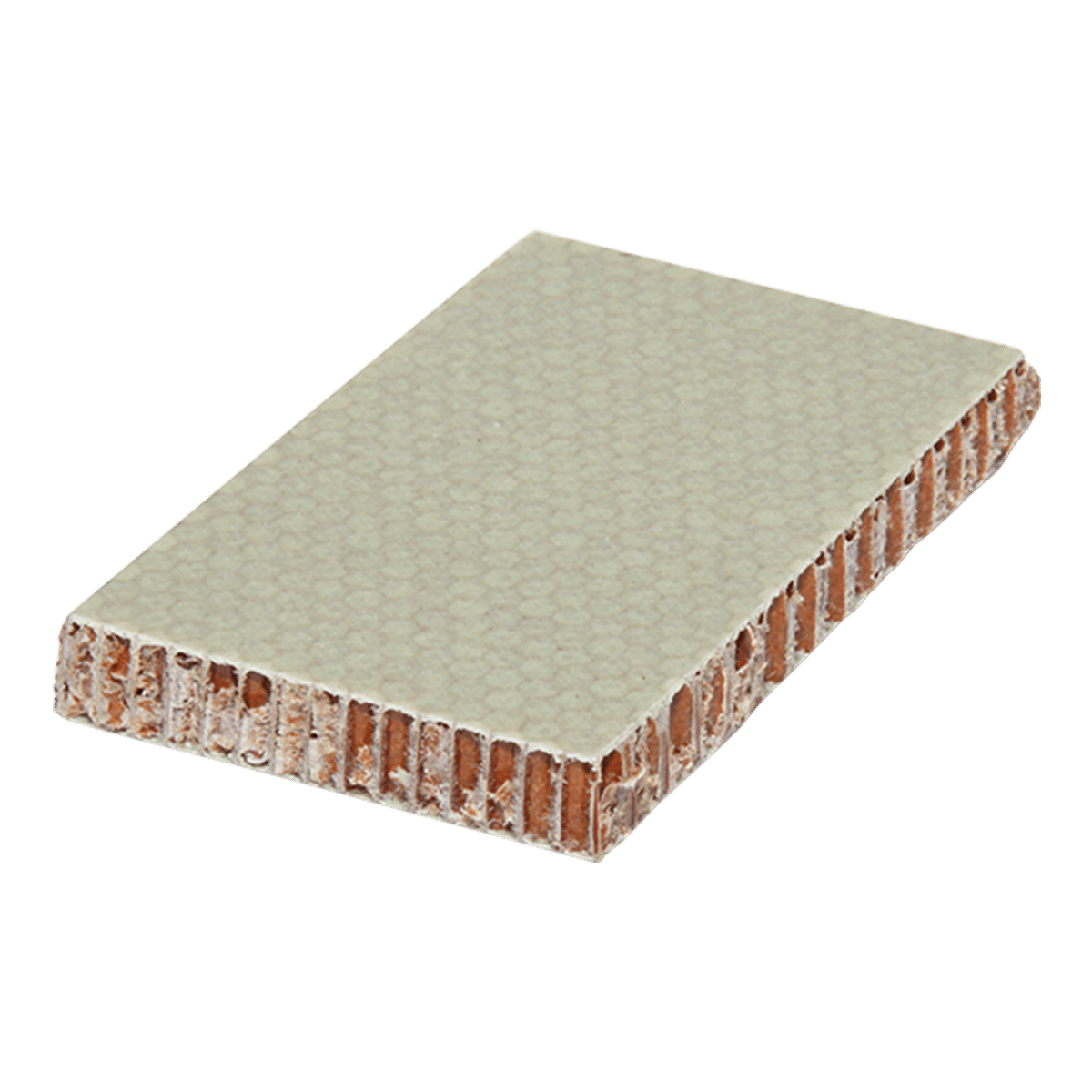

| Panel Weight, psf (kg/m2) | 0.537 (2.62) | 0.454 (2.22) | 0.819 (4.00) | 0.649 (3.17) | 0.718 (3.51) |

| Panel Thickness, inch (mm) | 0.242 (6.15) | 0.745 (18.92) | 0.995 (25.27) | 0.741 (18.82) | 0.746 (18.95) |

| Skin Thickness, face/back, inch (mm) | 0.020/0.020

(0.508/0.508) | 0.010/0.010

(0.254/0.254) | 0.010/0.010

(0.254/0.254) | 0.020/0.020

(0.508/0.508) | 0.020/0.020

(0.508/0.508) |

| Flatwise compression, psi (Mpa) | 491 (3.39) | 302 (2.08) | 286 (1.97) | 298 (2.05) | 622 (4.29) |

| Plate Shear Strength, lbs (N) | Ribbon | 278 (1,236) | 164 (730) | 144 (641) | 161 (716) | 229 (1,019) |

| Transverse | 135 (601) | 78 (347) | 71 (316) | 79 (351) | 133 (592) |

| Long Beam Bending, lbs (N) | Ribbon | 339 (1,508) | 253 (1,125) | 341 (1,516) | 556 (2,473) | 574 (2,553) |

| Transverse | 186 (827) | 281 (1,250) | 349 (1,552) | 348 (1,548) | 586 (2,607) |

| Short Beam Flexure, lbs (N) | Ribbon | 360 (1,601) | 253 (1,125) | 790 (3,514) | 708 (3,149) | 105 (467) |

| Transverse | 197 (876) | 351 (1,561) | 435 (1,935) | 350 (1,557) | 588 (2,616) |

| Drum Peel, in-lbs/3″ width (N-m/76mm width) | 76 (8.59) | 76 (8.59) | 56 (6.33) | 54 (6.10) | 49 (5.54) |

| Flammability | Meet FAR 25.853 App F Part I (a)(1)(i) |