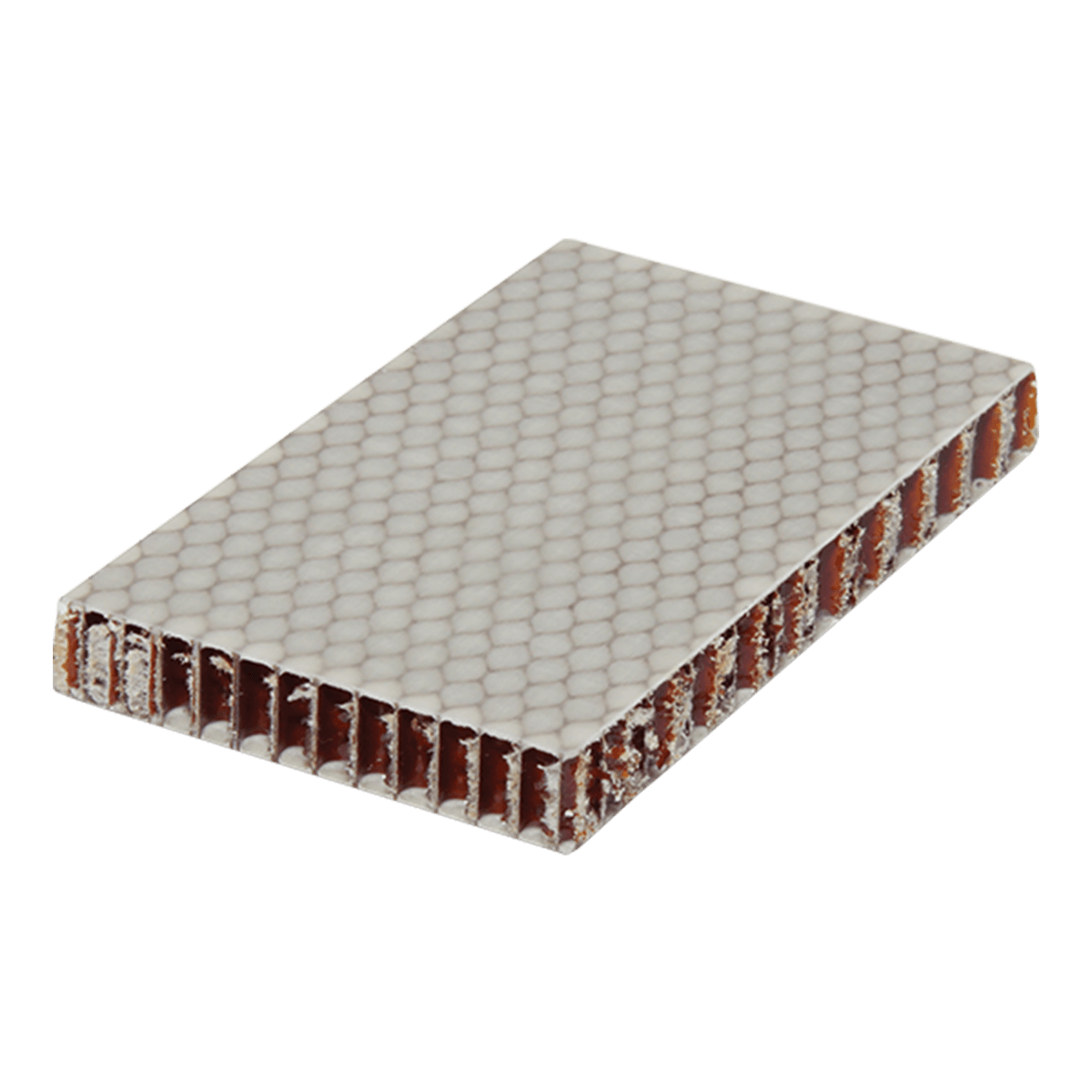

We are one of the world's largest manufacturers of honeycomb panels.

Providing innovative solutions for the world’s most crucial industries.

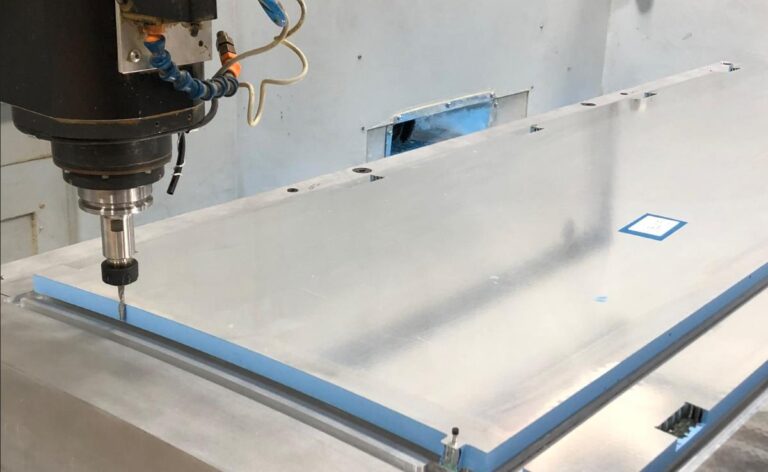

Capabilities

An extensive collection of documents, here at your fingertips.

Resources

Collaborating across continents to provide innovative composite solutions.